V-NASS, a.s. has more than 100 years of history, during which we have gained a lot of experience and built a great name and position not only in the Czech Republic but also in the world.

Our company was founded in 1917 under the name “Malostrojírna”; it was part of the Vítkovice Strojírny mining and metallurgical mining complex and focused on the production of mining equipment. After World War II, the production range was changed to the production of machine tools for the then Vítkovice company.

The modern history of V-NASS, a.s. begins in 1997, when it was separated from Vítkovice a.s. as part of privatisation and started its independent activity under the name V-NASS s.r.o.

In the following years, after a successful period of stabilisation and a change in the production programme with a focus on Oil and Gas, Nuclear Power and Metallurgy, the company experienced growth, which was crowned in 2006 by winning the Company of the Year 2006 award in the Moravian-Silesian Region. It also successfully increased its turnover and expanded the number of regions into which it penetrates with its products and permanently expands its technological capabilities in order to maximally satisfy the customer’s needs and offer the best possible service.

In 2011, the legal form was changed to a joint stock company.

In 2014, the company was awarded as the best supplier of the year by FMC, the world’s largest manufacturer of subsea oil production equipment.

At the end of 2016, it became a member of the Anacot Capital group, under whose leadership it successfully overcame the crisis in the oil markets, and in the following years it successfully built on our best results of the past.

Historie kovárny sahá do roku 1955, kdy byla postavena a uvedena do provozu jako součást národního podniku ZPS Hulín. V této době sloužila především pro výrobu volných výkovů pro oblast strojírenské a vojenské výroby.

Our vision is a company that maximally satisfies the needs of our customers. It is accommodating and is the customer’s partner. A company that is reliable, stable and provides customers with a long-term perspective. A company with which not only the customer but also the employee is satisfied and which is constantly developing and responding flexibly to trends in technology or business. We want to be an environmentally and socially responsible company and conduct all our activities in a way that benefits our environment.

We will take care of you and your needs. We offer a complete service for customers. We provide a comprehensive set of services, from the acquisition of the appropriate material, through production, surface treatment to transport to the destination. All services in the field of quality control, non-destructive testing or supervision by independent bodies are also included. Services that we are unable to provide ourselves are provided through an established network of suppliers. We work with reputable suppliers of surface treatments, special machining or testing. Our priority is uncompromising quality and emphasis on delivery dates and the possibility of changes during the execution of the order. We will prepare a tailor-made solution for each customer.

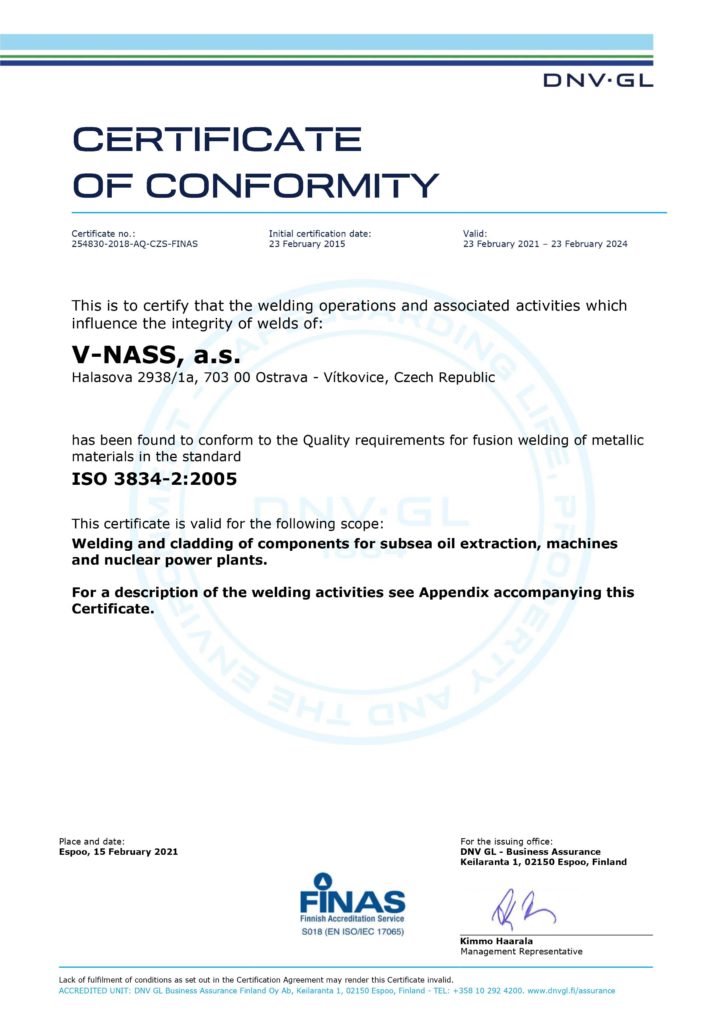

The quality and safety of our production is a top priority. The high standard of the quality level is ensured by two quality management systems ISO 9001:2015 and ISO 3834-2 certified by renowned companies TÜV NORD and DNV GL respectively. Due to the nature of the production in our company, strict adherence to the QMS rules is a matter of course. Our products are carefully monitored and managed from their ordering to the delivery of the final documentation to the customer. We apply a “ZERO defect” policy, the aim of which is to ensure that the customer always receives a product without deviations. Traceability is part of our process, which allows us to trace the history of the product back to the production of the base material with the utmost accuracy. Inspection, measurement and documentation are also an integral part of the entire quality assurance process. The portfolio of measurement tools and methods and our ability to create various types of documentation place us at the forefront of the industry.

TechnipFMC, GEBH (GE Baker Huges), One Subsea, Siemens, Vítkovice Cylinders, Třinecké železárny, Crust, Milmet, LN Scotland, Mondeléz, Škoda JS, JE Pács, Doosan, Ostroj Opava, VOP.

The project is focused on the implementation of cost-saving measures that will lead to a reduction in the energy requirements of V-NASS, a.s.’s operations. Specifically, it involves the replacement of existing energy-intensive machine tools with a new type with more economical electric drives and the replacement of the existing discharge lamp lighting with lighting with LED technology.

If you would like any further information, you can contact us using the email form below

or these contact details.

© 2023 2HEADS s.r.o. All rights reserved.